Evolve 55

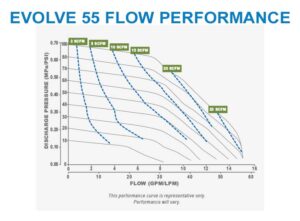

Max Flow: 57 LPM (15 GPM)

Max Temperature: 212 °F (100 °C)

Max Pressure: 100 PSIG (0.69 MPa)

Materials: PTFE/PFA fluid path

Perlast™ or PTFE fluid port adapter seals

Certifications: CE

Applications: Semiconductor/Electronics

LED/Flat Panel

Chemical

Chemical Processing

Delivery

Process

Slurry

Aerospace

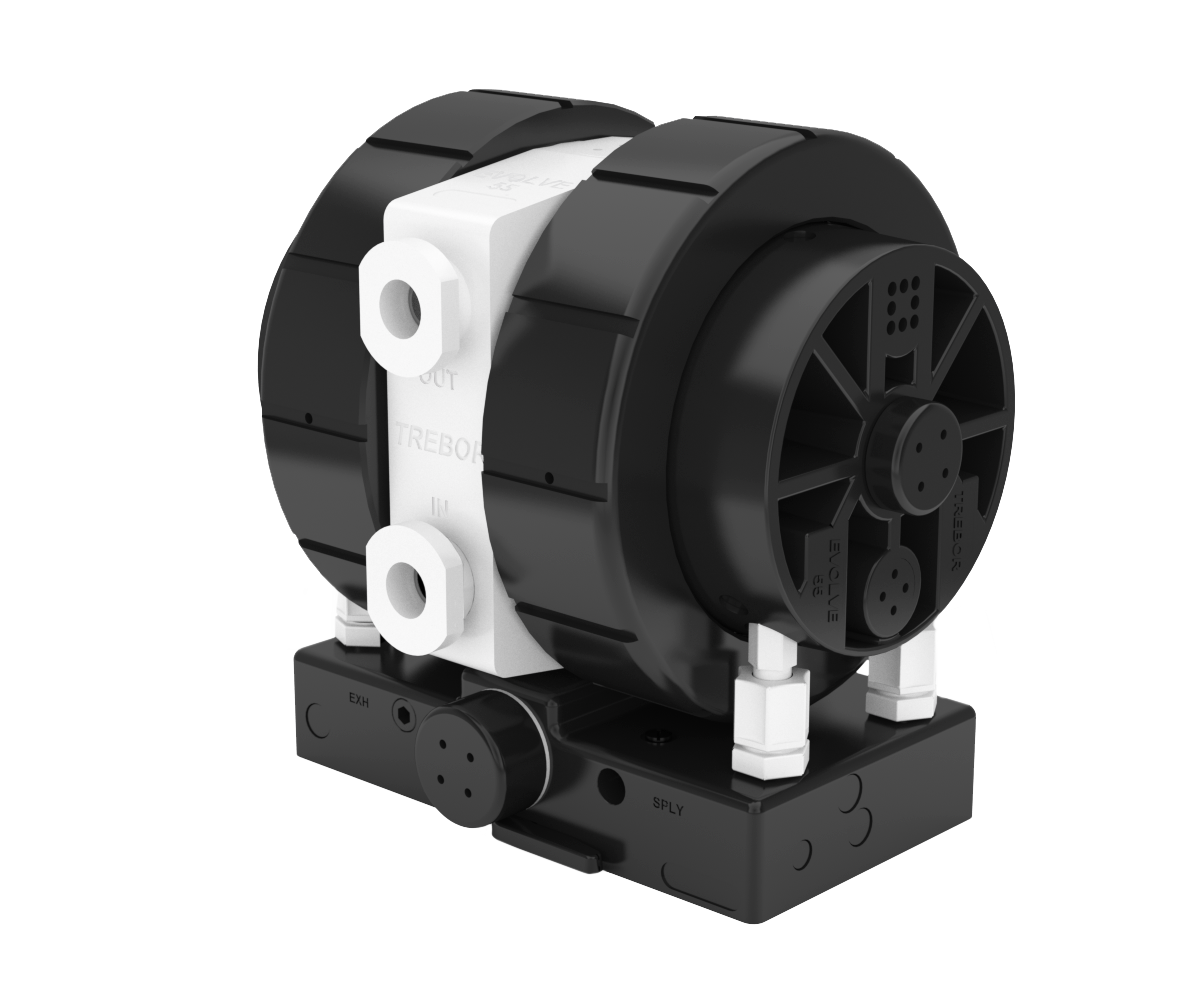

The Evolve 55 was engineered to improve cost, reliability, pressure capability, and flow rate starting from the classic and reliable M50 design. Working with our customers and vendors the Evolve 55 packs improved performance and longer life into the same footprint as the M50 at a lower cost. Diaphragm life is enhanced further by the Diffuser Head™ technology and patented seal design. The Evolve 55 is also available with the patented Magnetic Shuttle to reduce pneumatic wear and decrease the cost of ownership.

We focused on making improvements with cost as the driving factor. We worked with our suppliers to drive down costs and to improve our own manufacturing yields. In addition, the Trebor® team, along with our suppliers, developed a new method of manufacturing, called Precision Thermal Set Construction™, which combines molding and machining parts to allow for cost savings without compromising accuracy.

- Reliable Operation In Various Applications Because Of Patented Non-Stall Air Logic Design

- Safe, Pneumatic Operation With Clean, Dry Air, Or Nitrogen

- Non-Penetrated, Double Layer PTFE Diaphragms

- High Suction Capability Because Of Patented Floating PTFE Check Valves

- User Serviceable

- Clean Room Assembled, Tested, And Packaged

CONTROL STYLES

- Evolve 55D For Distribution And Deadhead Applications

FLUID PORT CONNECTIONS

- PTFE Gasket Adapter

- ¾” Pipe Stubout

- ¾” Tube Stubout

- ½” Flare

- ¾” Flare

- 1” Flare

- ¾” Pillar

- ¾” Female NPT

SURGE SUPPRESSOR

- SS85

- SS95

OTHER OPTIONS

- Leak Probe

- End Of Stroke Probe

- Cycle Probe

- Magnetic Shuttle (E55D only)

DATASHEET

MANUAL

CAD FILE/DRAWING