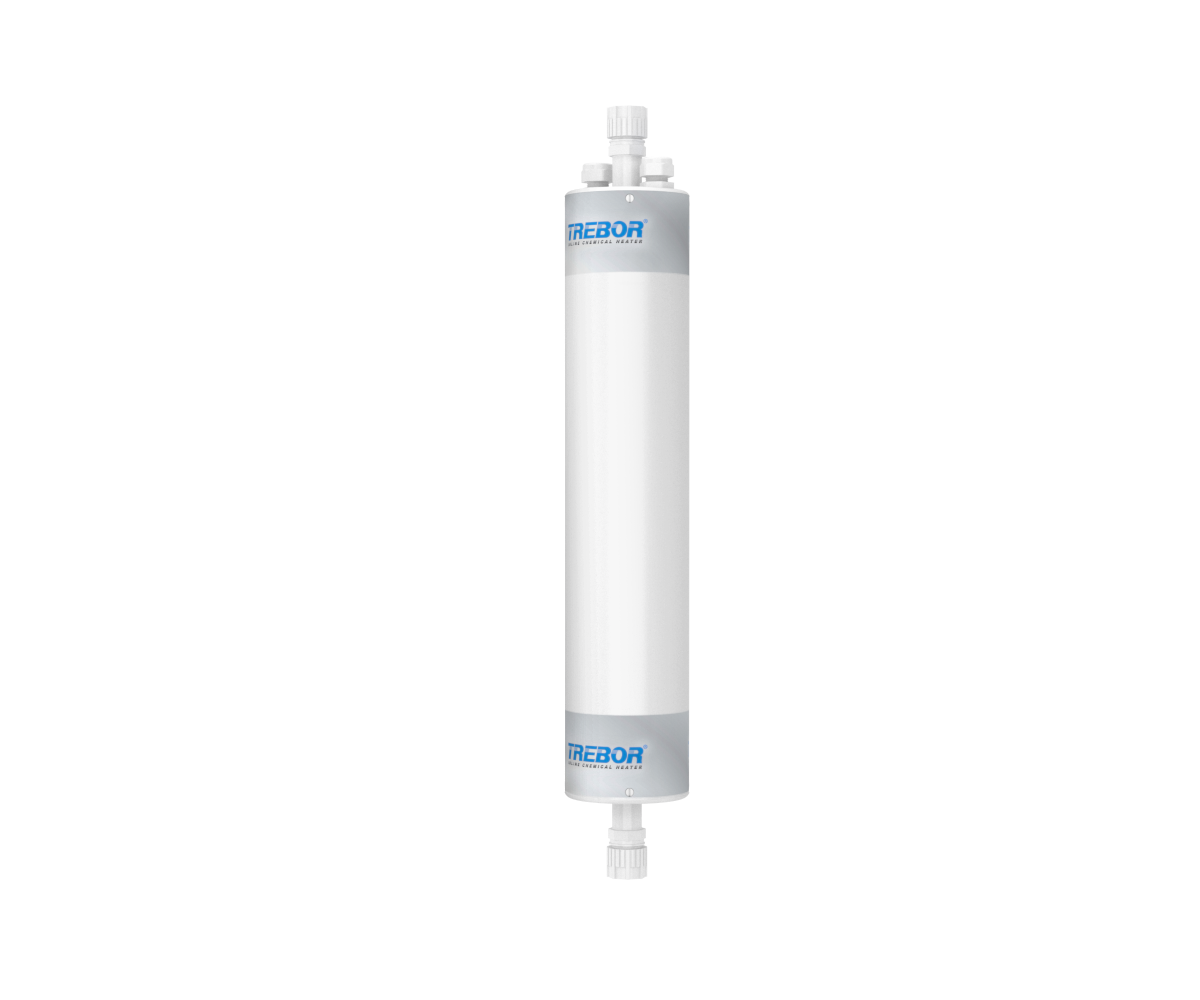

Inline Chemical Heater

Max Flow: 28 LPM (7 GPM)

Max Temperature: 212 °F (100 °C) - ICA

392 °F (200 °C) - ICB

Max Pressure: 80 PSIG (0.55 MPa)

Materials: Quartz element with housing options (PTFE, PFA, Stainless Steel)

Power: 3, 4, or 6 kW combinations

single phase or three phase

Voltage: 208

400

Certifications: CE, Semi S2 & S3

Applications: Semiconductor/Electronics

LED/Flat Panel

Solar

Chemical

Chemical Processing

Process

Aerospace

Trebor’s Inline Chemical Heaters are unlike any other heating technology on the market because of our thin film on quartz electric resistive technology. Our technology, combined with high-purity materials, a quick ramp up time, crevice-free design, and customizable configurations, creates reliable and efficient heater.

Because of the design simplicity and flexibility, we can accommodate a wide range of application needs with only two models – a high temperature version and a low temperature version. These heaters are well-suited as a plug-and-play design for a variety of applications, especially with fluids that need to be heated quickly and at point-of-use.

- High Purity Flow Path Made Of GE214 Quartz

- PFA Tubing For Safety And Purity

- Crevice-Free Flow Path Means No Bacteria Growth Or Purging Required

- Compatible With All Acids, Except KOH And HF

- No Risk Of Metal Contamination

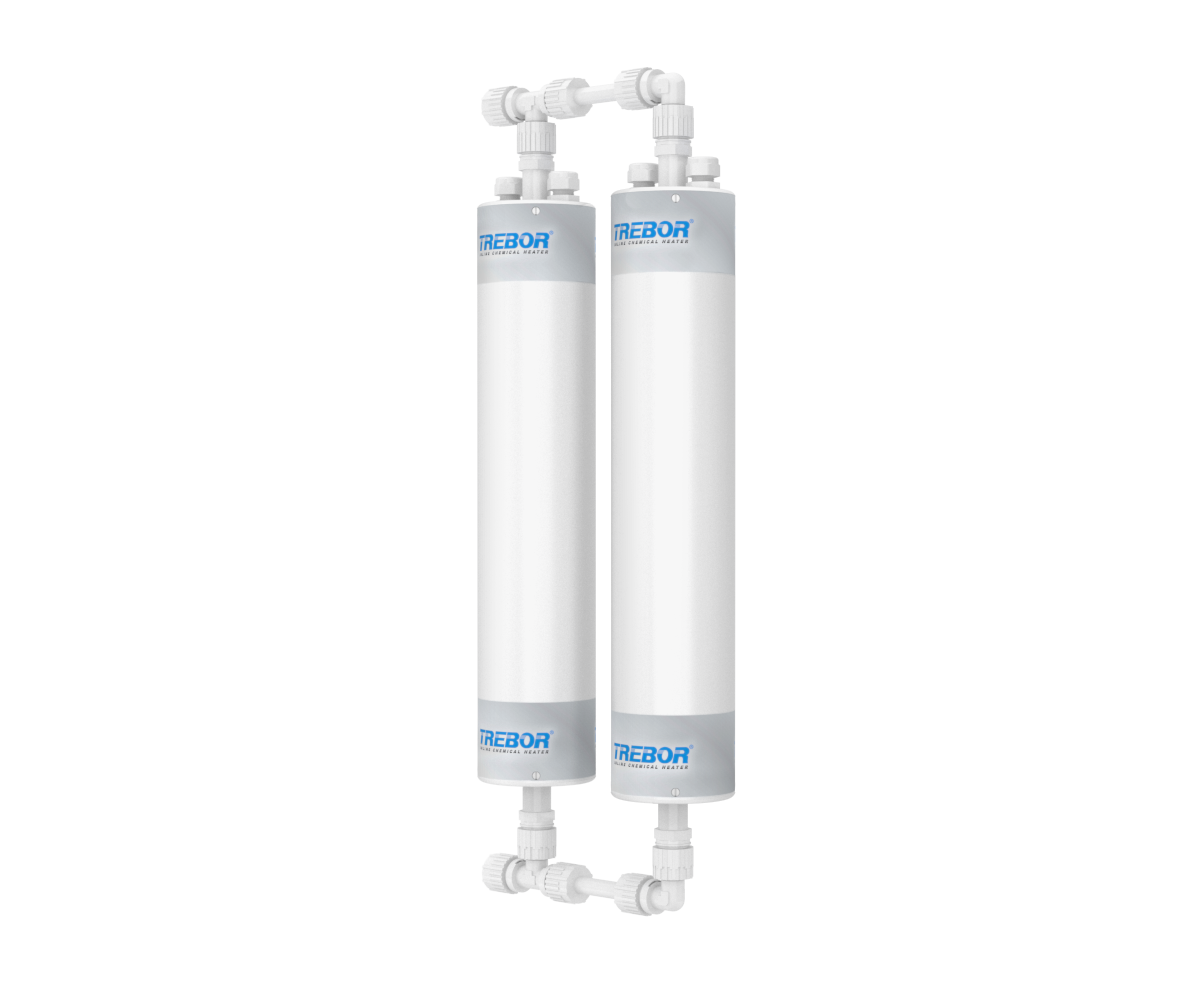

- Series Or Parallel Configuration Available

- Multiple Voltage And Kilowatt Options

- Strong Construction And Performance Because Of Patented Sealing Technology

- Customizable Configuration For Power, Space, Fluid Connections And Other Process Needs

Need help with selecting a chemical heater? Please see our Chemical Heater Selection Guide.

POWER/VOLTAGE

- Customizable Starting At 3kW 208V

- Customizable Starting At 3kW 400V

FLUID PORT CONNECTIONS

- Custom Options Available

OTHER OPTIONS

- Liquid Level Sensors

- Leak Sensors

- Over-Temperature Interlocks

MANUAL

Inline Chemical Heater – MANUAL

DATASHEET

Inline Chemical Heater – DATA SHEET

CERTIFICATION

Declaration of Conformity (Doc) Inline Heaters (IQ, IC, and ID) (PDF)

CAD FILES/DRAWINGS