Mega 255

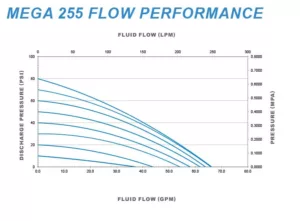

Max Flow: 255 LPM (67 GPM)

Max Temperature: 212 °F (100 °C)

Max Pressure: 80 PSIG (0.55 MPa)

Materials: PTFE/PFA fluid path

All wetted seals are PTFE

Certifications: CE

Applications: Semiconductor/Electronics

LED/Flat Panel

Chemical Processing

Delivery

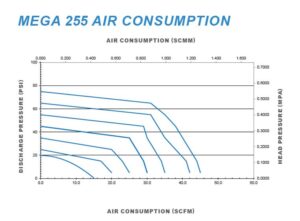

The Mega 255 is ideal for high flow chemical delivery applications. This pump features Trebor® non-centering magnetic shuttle that is proven zero maintenance shuttle prevents stalling that is caused by “centering”. This innovation ensures maximum MTBF for the pump as well as the avoidance of interruptions to chemical supply that can negatively impact critical processes. The fluid path is constructed entirely of PFA and PTFE to ensure high-purity pumping and chemical compatibility. The non-metallic air chamber components make this pump suitable for use in aggressive acid vapor environments. The Mega 255 uses proven pump technology to consistently meet aggressive high flow fluid handling needs. High back pressure, no problem. Our intelligent pneumatic control ensures that the pump will not switch pressure to the pump chambers until the diaphragm has made a complete stroke, enabling deadhead capable operation.

- Free Floating Double Diaphragm

- High Suction Capabilities

- Non-Centering Magnetic Shuttle

- High Backpressure And Deadhead Capable

Control Styles

- 255D for Chemical Delivery

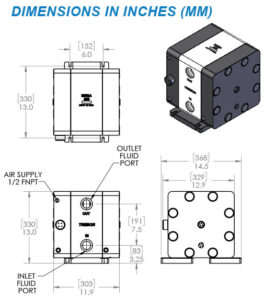

Fluid Port Connections

- 255B16 1″ PFA Pipe Stub

- 255B24 1 1/2″ PFA Pipe Stub

- 255P16 1″ PTFE Flare NPT

- 255P24 1 1/2″ PTFE Flare NPT

Surge Suppressor

- SS95P5A0 Surge Suppressor

OTHER OPTIONS

- Fiber Optic Probes

- Cycle Counter

- Leak Sensors